flat ring pellet mill

مجال التطبيق

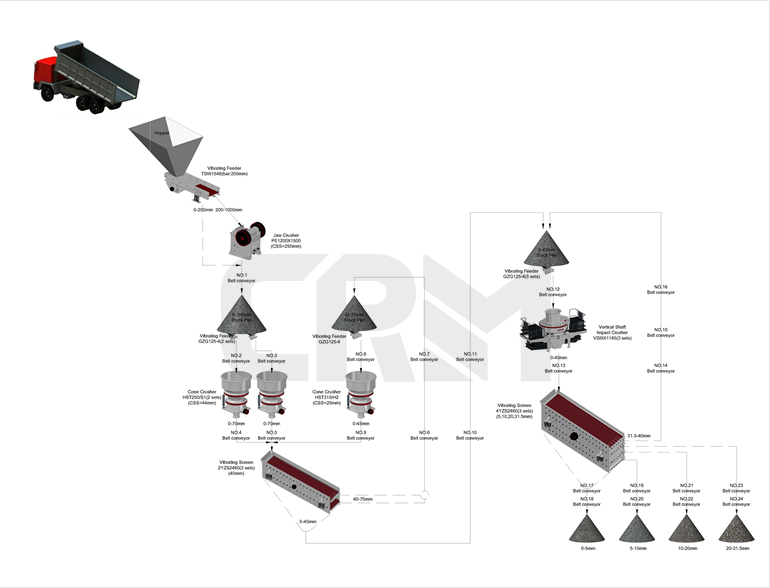

خط إنتاج معالجة البوكسيت 200TPH في غينيا

تم الإشادة بنظام التحكم الذكي Liming Heavy Industry. تمكننا من مراقبة خط الإنتاج المحلي في الوقت الفعلي ومعرفة معلومات الموقع في الوقت المناسب ، مما يوفر راحة كبيرة لإدارتنا.

المعدات: كسارة فكية PE750x1060 ، كسارة مخروطية هيدروليكية HPT300

المواد: البوكسيت

السعة: 200 طن / ساعة

حجم المدخلات: 600 مم

حجم الإخراج: 0-20mm.

التطبيق: إنتاج سبائك الألومنيوم ، التصنيع الحراري

Flat die pellet mill and ring die pellet mill comparison

2014年4月4日 1. Price: The flat die pellet mill is far cheaper than that of the ring die pellet mills. 2. Capacity: The output capability of the flat die pellet mill ranges from

Densification of biomass using a pilot scale flat ring roller pellet mill

2016年7月1日 The production characteristics from a pilot scale flat ring die pellet mill were evaluated for four different biomass materials (miscanthus, corn stover,

Typical pellet mill design a) ring die and b) flat die

A die with press channels and roller (s) are the basic parts of a pellet mill. The die can either be in the shape of a ring or a flat plate, as shown in Fig. 2.

Review of die design and process parameters in the

2020年3月15日 The pressure required for pelleting the feedstock tends to decrease linearly when increasing the moisture content in the range 0–25% [12,22]. After conditioning the

Design and experiment of flat die pellet mill with plunger

Design and experiment of flat die pellet mill with plunger. Chen Zhongjia , Yu Guosheng , Wang Qingyu , Yuan Xiangyue , Ning Tingzhou , Jin Shi. School of Technology, Beijing

An introduction to the pellet mill (1)

2015年7月9日 The flat die pellet mill preceded the ring die mill and is more commonly used for small- to mid-scale pelletization. In contrast, ring die pellet mills are more commonly used in industrial scale pellet

Design and experiment of flat die pellet mill with plunger

2015年10月1日 The self-developed flat die pellet mill mainly consisted of three parts: a flat die, plungers, and a swash plate. When the swash plate rotated, it drove the rolling

Pellet mill design - Feed Strategy

A pellet mill is considered to be the type of machine that can be subjected to “shock loads”, so there is typically at least a 2:1 safety factor built into the design of the main driving

Pellet mill die and roll design - Feed Strategy

The basic physical properties of pellet mill die materials are controlled by the composition of the steel used and the heat-treating process. The two key elements in dies are carbon

سابق: المواد كسارة المحمول

التالي: بور، لي، حجر، كسارة الفك

2-12-24SERVICE MECHANISM

Common choice of more than 170 countries

Email:[email protected]

المحادثة على الإنترنت

المحادثة على الإنترنت