Quation For Jaw Crushers

مجال التطبيق

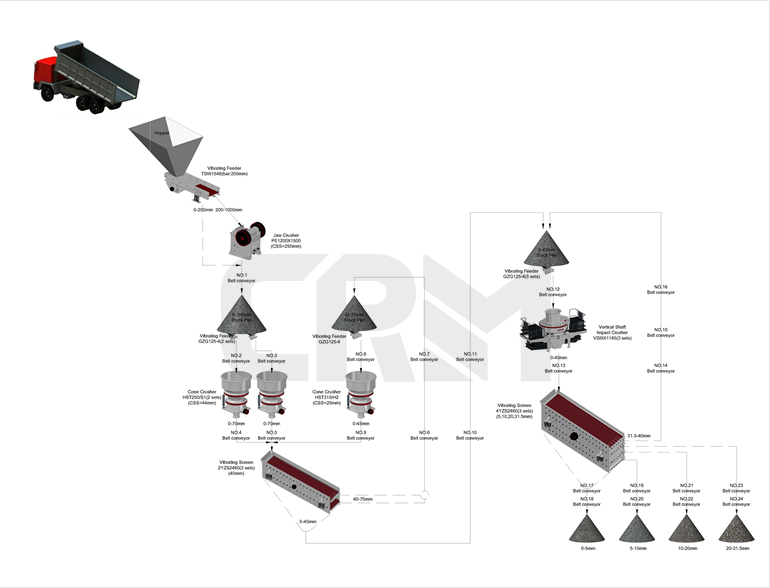

خط إنتاج معالجة البوكسيت 200TPH في غينيا

تم الإشادة بنظام التحكم الذكي Liming Heavy Industry. تمكننا من مراقبة خط الإنتاج المحلي في الوقت الفعلي ومعرفة معلومات الموقع في الوقت المناسب ، مما يوفر راحة كبيرة لإدارتنا.

المعدات: كسارة فكية PE750x1060 ، كسارة مخروطية هيدروليكية HPT300

المواد: البوكسيت

السعة: 200 طن / ساعة

حجم المدخلات: 600 مم

حجم الإخراج: 0-20mm.

التطبيق: إنتاج سبائك الألومنيوم ، التصنيع الحراري

Capacities and performance characteristics of jaw crushers

The final equation for the capacity of jaw crushers can now be written as W = Vh K1 K2 KS d (9) where K1, K? and K3 are related to the parameters F,,/G, TI G and the nature of the

5 Common Questions about Jaw Crushers Answered

2019年5月30日 Home; Concrete; 5 Common Questions about Jaw Crushers Answered. There are many types and styles of crushing equipment. Kemper Equipment explains how to choose the right crusher

Jaw Crusher - an overview ScienceDirect Topics

Jaw crushers are mainly used as primary crushers to produce material that can be transported by belt conveyors to the next crushing stages. ... From the equations, it can be seen that once the gape has an assigned value the rest of the dimensions follow.

“Computer Aided Design of Jaw crusher” - 911 Metallurgist

Jaw crusher movement is guided by pivoting one end of the swinging jaw. and an eccentric motion located at the opposite end. [4] The size of a jaw crusher is designated by the rectangular or square opening at the top of the jaws .For instance, a 22 x 30 jaw crusher has an opening of 22" by 30", a 46 x 46 jaw crusher has a opening of 46" square.

Energy consumption values of each crusher per tonne

Download Table Energy consumption values of each crusher per tonne from publication: Development of a model estimating energy consumption values of primary and secondary crushers Most of the ...

Jaw Crusher Working Principle - 911 Metallurgist

2021年5月6日 A sectional view of the single-toggle type of jaw crusher is shown below. In one respect, the working principle and application of this machine are similar: the movable jaw has its maximum movement at the top of the crushing chamber, and minimum movement at the discharge point. The motion is, however, a more complex one than the

Estimate Jaw Crusher Capacity - 911 Metallurgist

2016年2月17日 Single-toggle jaw crusher specs. The selection of an appropriate primary crusher for a given use has to be based on a consideration of several factors.

Crushing Products Size and Shape -What to Expect

2016年2月26日 Such an arrangement is seldom encountered in modern plant design, except where large jaw crushers, set very wide, are followed by a secondary, usually of the standard gyratory type, to reduce further the very coarse output of the jaw crusher to a size which can be handled by the recrushing, screening, and elevating equipment in the

(PDF) DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE JAW CRUSHER ...

2017年6月30日 A review on the design and operations challenges of a single toggle jaw crusher is presented. Strength and fracture toughness of the material to be crushed are intrinsic properties that determine ...

Bond Impact Crushing Work Index -Procedure and Table of Crushability

2015年6月16日 The test determines the Bond Impact Work Index which is used with Bond’s Third Theory of Comminution to calculate net power requirements when sizing crushers*. It is also used to determine the required open-side settings (jaw crushers and gyratory crushers) or closed-side settings (cone crushers) for a given product size.

Jaw Crushers for Sale or Rent Jaw Crusher Parts, Service

Power Screening jaw crusher sales, rental, parts service. Locations in Henderson, CO Albuquerque, NM. We're here to answer your jaw crusher questions.

Crushing Products Size and Shape -What to Expect

2016年2月26日 I have made a number of general remarks regarding the character of product delivered by crushers of various types, and under different conditions of operation. Generalities are of value only if we have

“Computer Aided Design of Jaw crusher” - 911 Metallurgist

Jaw crusher movement is guided by pivoting one end of the swinging jaw. and an eccentric motion located at the opposite end. [4] The size of a jaw crusher is designated by the rectangular or square opening at the top of the jaws .For instance, a 22 x 30 jaw crusher has an opening of 22" by 30", a 46 x 46 jaw crusher has a opening of 46" square.

Jaw Crusher: What Is It How Does It Work? - Vykin Machinery

However, jaw crushers can also be found in other applications, such as recycling materials or separating minerals from ore. To learn about The Importance Of Performing Market Research, Click here! Types Of Jaw Crushers. There are two main types of jaw crushers: jaw crushers that use stationary jaw plates and jaw crushers that use movable jaw ...

Influence of jaw crusher parameters on the quality of primary

2020年6月1日 The data presented here is limited to a single rock type and a single jaw crusher. A natural continuation of this research would be to extend the test programme to include several rock types of varying strength and brittleness. Another possibility is to include other jaw crushers to assess the effect of crusher geometry. 5. Conclusions

How it Works: Crushers, Grinding Mills and Pulverizers

2017年6月2日 The equation for Rittinger’s Law can be written as: E = K R f c (1/L 2 – 1/L 1) Where: E=Energy, ... Jaw crushers use mechanical pressure to break the material by forcing it between two vertical jaws, one stationary and one that is driven back and forth.

Dynamics Analysis and Chaos Identification of Compound Pendulum Jaw ...

2022年12月24日 Jaw crushers are utilized extensively in the industries of mining, metallurgy, building materials, ceramics, and engineering of massive minerals with small and medium particle size crushing [1,2,3].There are now more demands on crushers in terms of efficiency, energy use, and cost due to new issues including the rise in low-quality ore,

Jaw crushers, Stationary Jaw crusher series - SRP

Sandvik Jaw crushers come with everything you need for plug-and-play primary crushing operations. Each jaw crusher comes with feed hopper, feed hopper interface, drive and subframe with v-belt guard and motor bracket, our unique guarding retraction arrangement and toggle plate stop.

What Is A Jaw Crusher - MEKA

Jaw crushers are generally defined by their opening size. For example, a 900x650 mm crusher refers to a crusher with an inlet measuring 900 mm by 650 mm. The main parts and main technical parameters of a jaw crusher are presented below. 1. Feed Chute 2. Drive Flywheel 3. V-belts 4.

Understanding Jaw Crusher Parts and Their Functions - AGICO

2023年2月23日 Introduction: Jaw crushers are powerful machines that are widely used in the mining, quarrying, and recycling industries. These machines are designed to crush large rocks and ores into smaller pieces for further processing. A jaw crusher consists of a fixed jaw and a movable jaw, with the latter being driven by an eccentric shaft that moves the

What is a Jaw Crusher and Selecting the Right One - Gilson Co.

Jaw crushers feature safe, simple operation and maintenance. Disadvantages of a Jaw Crusher. Jaw crushers can also have some disadvantages compared to other types of size reduction. Opposing jaw plates are less efficient at reducing materials that are tough, ductile, or soft instead of hard and brittle.

سابق: الفحم المحمولة المفرق

التالي: غرامة محطم المزدوج الدوار

2-12-24SERVICE MECHANISM

Common choice of more than 170 countries

Email:[email protected]

المحادثة على الإنترنت

المحادثة على الإنترنت