grinding and smoothing materials resulting from the crushing process

مجال التطبيق

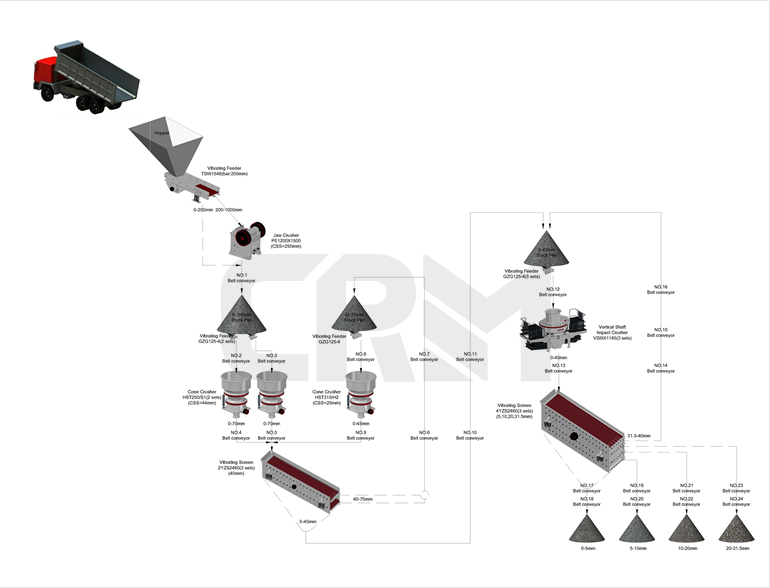

خط إنتاج معالجة البوكسيت 200TPH في غينيا

تم الإشادة بنظام التحكم الذكي Liming Heavy Industry. تمكننا من مراقبة خط الإنتاج المحلي في الوقت الفعلي ومعرفة معلومات الموقع في الوقت المناسب ، مما يوفر راحة كبيرة لإدارتنا.

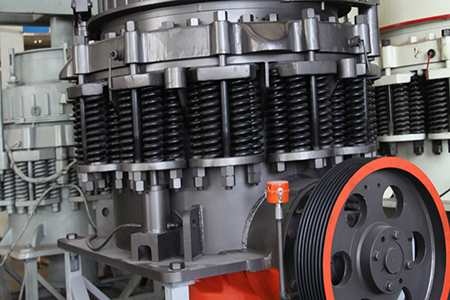

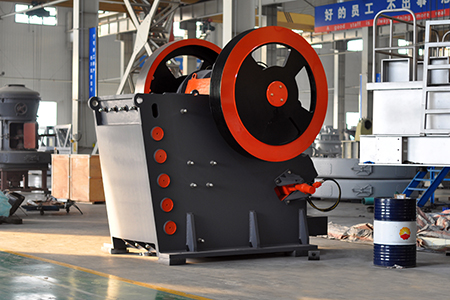

المعدات: كسارة فكية PE750x1060 ، كسارة مخروطية هيدروليكية HPT300

المواد: البوكسيت

السعة: 200 طن / ساعة

حجم المدخلات: 600 مم

حجم الإخراج: 0-20mm.

التطبيق: إنتاج سبائك الألومنيوم ، التصنيع الحراري

Grinding of composite materials - ScienceDirect

2023年1月1日 Introduction. Continuous progress of science and technology has led to an increasing requirement for high-performance engineering materials. Traditional metals,

Material removal mechanism and corresponding models in the

2023年10月6日 To understand the current status and future trends of material removal in the grinding process, this paper adopts a systematic review approach to summarize the

Mass balance resulting from the crushing and grinding stages.

A mass balance, assuming negligible losses, for 5 kg of materials resulting from crushing and grinding is plotted in Figure 5. The impact crusher, selected as the first stage of

Effect of grinding damage on cutting force and ductile machining

2022年11月15日 This paper discusses the effects of grinding damage on material removal mechanism from the perspectives of residual scratch depth, scratch morphology

Principles of Sample Preparation by Grinding or Comminution

Principles of particle reduction. The most common method for obtaining a homogeneous sample is grinding of comminution. Grinding samples has many benefits for sample

Metallographic grinding and polishing insight Struers

Learn how to improve the quality and speed of your metallographic grinding and polishing – from selecting the best method to choosing the right consumables – with expertise, tips

Grinding and Abrasive Machining of Composite Materials

2021年6月22日 This chapter focuses on the grinding of polymer matrix composites (PMCs), metal matrix composites (MMCs), and ceramic matrix composites (CMCs) and

Study of the Grinding Process by Friction of Cereal Grains in

2023年12月6日 The grinding process via friction at the micro-scale in a mill with stones is considered a variable combination of contacts, with two-body (the asperities of lower

Improving the efficiency of the material grinding process

2020年10月27日 The paper provides an analysis of grinding systems used in the world practice, including the main technical solutions in the field of fine grinding of materials

Metallographic grinding and polishing insight

Learn how to improve the quality and speed of your metallographic grinding and polishing – from selecting the best method to choosing the right consumables – with expertise, tips and insight from Struers, the world’s

The crushing of wheat kernels and its consequence on the grinding process

2008年7月1日 According the classification proposed by Williams [18] Turnia was classified as hard and Rapsodia as soft wheat (HI = 71 and 32, respectively). The results of specific kernel crushing energy (E cs) are presented in Table 1.For both cultivars, as the kernel moisture increased from 10 to 18% the E cs slightly increased. When the moisture was

Physical Weathering: The Mechanical Breakdown Of Rocks

2024年6月11日 This fundamental geological process of physical weathering involves the mechanical breakdown of rocks without any chemical ... The grinding and wearing away of rocks through wind, water, ... the water trapped within the rock pores and cracks starts to solidify. However, unlike most materials that contract upon solidification, ...

Principles of Sample Preparation by Grinding or Comminution

Sample preparation is the process where a representative piece of material, ... Sample size reduction is accomplished by either crushing or grinding using forces of impact, ... a large size difference between the coarse material and the fine resulting particles. E = K R E = K R (S n - S i ( or) (1-1 d 2 d 1

POWER ANALYSIS OF THE PROCESS OF BRITTLE MATERIALS

2019年6月20日 The processing of friable materials used in metallurgical industry for production of definite size classes requires operation of crushing machines, including single-roll machines. Parameters of crushing process are degree and efficiency of crushing. The crushing degree is estimated by the ratio of dimensions of the initial

Mechanical behavior and modeling of grinding force: A

2023年9月29日 Currently, scholars consider the grinding force modeling mainly from the material, grinding process, ... When grinding alloy steel, higher grinding forces, temperatures, and surface roughness are generated, resulting in accelerated abrasive wear. Download: Download high-res image (656KB) Download: Download full-size image;

Improving the efficiency of the material grinding process

2020年10月27日 The paper provides an analysis of grinding systems used in the world practice, including the main technical solutions in the field of fine grinding of materials using a ball mill, and also ...

Dolomite Crushing Process And Grinding Equipment

2024年3月12日 (2) If the grinding fineness is between 400-800 mesh, ultra-fine vertical grinding and medium-speed micro grinding can be selected. These grinding machines have high grinding fineness, low energy consumption, and high cost-effectiveness. (3) If the grinding fineness exceeds 1000 mesh, use an ultra-fine grinding machine.

Grinding Process SpringerLink

During a machining process with a track-bound cutting edge engagement, the cutting edge of the grain penetrates the workpiece upon a flat path and, after a phase of elastic deformation, triggers plastic flow of the workpiece material (Fig. 3).Due to the shape of the cutting edge, the angle between the cutting edge contour and the workpiece surface is

A review of the influence of grinding conditions on resulting

2001年8月7日 Brinksmeier [19] presented numerous experimental results obtained in grinding of hardened steel under various grinding conditions and with different kinds and grain sizes of the grinding material in terms of force measurement, grinder wear with regard to material removal from the workpiece during the grinding process, as well as

Materials Free Full-Text Probabilistic Aspects of

2022年8月26日 In this article, the methodology of using probabilistic models of the grinding tool wear process is presented. Probabilistic modeling with empirical data allowed determining the values of other

grinding - definition and meaning - Wordnik

The mode of grinding corn here, if I may use the term grinding, is of the most primitive character possible.. Travels in the Great Desert of Sahara, in the Years of 1845 and 1846 James Richardson 1828. Especially the term grinding, because no other gamer jargon inspires as much innuendo.. Gamasutra Feature Articles 2010. The main reason that the

Difference between Crushing and Grinding - 911 Metallurgist

2017年2月17日 When making comparisons of the efficiencies of different grinding and crushing machines it is desirable to be able to estimate the work actually done in crushing the ore from a given size of feed to a given size of product, the screen analysis of both feed and product being determined. Messrs. Klug and Taylor, in a paper on this subject,

The crushing of wheat kernels and its consequence on the grinding process

2008年7月1日 The effect of crushing the kernel and moisture content on the grinding behavior of wheat has been investigated. Crushing of the wheat kernel prior to hammer mill grinding has a significant influence on the grinding process, both on specific grinding energy and particle size distribution of the ground material, especially for soft wheat

Residual stress generation in grinding: Mechanism and modeling

2024年3月1日 1. Introduction. Grinding is a finishing process (Pawlus et al., 2023), which holds a pivotal and widespread position across various domains (Satyanarayana and Nancharaiah, 2018), including the mechanical, automotive, aviation, aerospace, construction, and medical industries.The grinding-induced residual stresses, arise from

Understanding the Difference Between Crushing Grinding in Material

2024年6月26日 The material is subjected to grinding process in between two surfaces moving towards each other at varying speeds, thereby creating fine, even product. Stages of Grinding. Crushing occurs in stages, unlike grinding, which just has a beginning, middle, and end as per the desired fineness of the output.

Crushing in Mineral Processing - Eastman Rock Crusher

2020年4月20日 Crushing is the process of reducing the size of materials so that they can be further processed. In addition to being used in the chemical, coal industry, constrction area and so on area, industrial crushing equipment can be very useful in

Surface Grinding: A Guide to the Process and Precision

2024年1月11日 Precision grinding is achieved through careful control of the grinding operation. For specific applications, surface grinders can be equipped with different wheels, including CBN grinding wheels. The grinding process removes excess material and achieves smooth surface finishes, essential in applications requiring finely finished surfaces.

Crushing Grinding

2023年11月25日 Crushing and grinding are fundamental processes in various industries. Crushing involves reducing large particles into smaller ones, often to extract valuable minerals or prepare raw materials for ...

(PDF) Comminution a Heart of Mineral Processing - ResearchGate

2021年7月6日 Crushing and grinding are known as comminution procedure where the major operations are intensively related to liberation and reduction of particle size by means of different technologies.

2-12-24SERVICE MECHANISM

Common choice of more than 170 countries

Email:[email protected]

المحادثة على الإنترنت

المحادثة على الإنترنت