preheater in cement industries

مجال التطبيق

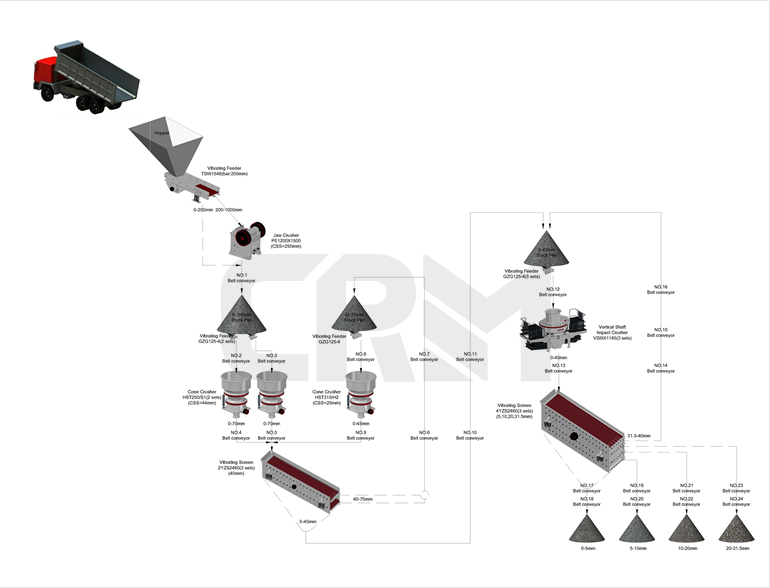

خط إنتاج معالجة البوكسيت 200TPH في غينيا

تم الإشادة بنظام التحكم الذكي Liming Heavy Industry. تمكننا من مراقبة خط الإنتاج المحلي في الوقت الفعلي ومعرفة معلومات الموقع في الوقت المناسب ، مما يوفر راحة كبيرة لإدارتنا.

المعدات: كسارة فكية PE750x1060 ، كسارة مخروطية هيدروليكية HPT300

المواد: البوكسيت

السعة: 200 طن / ساعة

حجم المدخلات: 600 مم

حجم الإخراج: 0-20mm.

التطبيق: إنتاج سبائك الألومنيوم ، التصنيع الحراري

The design of cyclonic pre-heaters in suspension cement kilns

The design of a cascade of cyclonic pre-heaters in suspended cement kilns, and the overall energy economy of the system, can be improved. The factors in the optimum design are

Preheater In Cement Plant - Cyclone Preheater AGICO

Cyclone preheater, also known as suspension preheater, is the main equipment in the clinker calcination process. AGICO offers quality 5-stage cyclone preheater which combined with precalciner widely used in dry

Preheater - KHD Humboldt Wedag

From separators and cyclones to splash boxes, flap boxes and dip tubes, we supply all of the parts that go into a state-of-the-art preheater. All designed to achieve the optimal combination of heat transfer, pressure drop,

Control of Precalciner Temperature in the Cement

The pre-calcination system is one of the most critical steps in the dry process cement process. The exothermic reaction of the precalciner fuel and the heat-absorbing decomposition reaction of the cement raw meal

CFD simulation of the preheater cyclone of a cement plant and the ...

The first-stage cyclones' efficiency in the preheater system of a cement plant is very important. In this study, one of the twin cyclones in the first-stage of the preheater in the

Cement Plant Cyclone Preheater

By using the computer numerical simulation technology to simulate the gas-solid two-phase flow field of the cement plant preheating system, we can design the optimal cyclone preheater according to the specific

Cyclone Preheaters: Better throughput; less spend

Proven NOx reduction from high temperature “stage-less” combustion is incorporated into the standard design of the ILC preheater. It’s a very uncomplicated and effective way to create low NOx emissions with only

Health and safety in cyclone-preheaters World Cement

Occupational health and safety has top priority within the cement industry. Hot areas and cyclone-preheaters in particular are among the most dangerous places in a cement

Carbon Capture in the Cement Industry: Technologies,

2015年12月2日 Several different carbon-capture technologies have been proposed for use in the cement industry. This paper reviews their attributes, the progress that has been made toward their commercialization, and the

Centrifugal Fans in Cement Industry: Crucial Roles Applications

2023年12月23日 Explore how centrifugal fans power cement production, their pivotal roles in cooling, ventilation, material handling. Discover Techflow's range for optimal performance.

WHRB in Cement Plant - Thermax

Cement manufacturing is a highly energy-intensive process. Given the fragile and dynamic nature of the fuel and power situation faced by cement plants today,

Cement kiln - Wikipedia

Hot end of medium-sized modern cement kiln, showing tyres, ... A preheater tower, rawmix silo and exhaust stack. Bottom left: rawmill. ... (they are paid by industries needing to dispose of materials that have energy content and can be safely disposed of in the cement kiln thanks to its high temperatures and longer retention times).

Recent development on the uses of alternative fuels in cement ...

2015年4月1日 A wide range of alternative fuel sources can be used in cement industries. Cement rotary kiln is able to burn a wide range of materials due to the long residence times at high temperatures, intrinsic ability of clinker to absorb and lock contaminants such as heavy metals into the clinker and the alkaline environment of the kiln.

Preheater - KHD Humboldt Wedag

Every cement plant needs a preheater. But what exactly is it? Think of it like a big box. A big box that holds a number of different machines. Combined, these machines kick off the pyroprocess. It might sound a simple concept. But putting the pieces together to achieve best-possible performance requires an expert understanding not only of the process but

Mastering Process Control Instrumentation in Cement Plants: A ...

2023年9月5日 Instrumentation in Cement Industries plays a pivotal role in ensuring the smooth operation of the entire manufacturing process. ... These include temperature and pressure sensors for the preheater and the kiln, gas analyzers to

Waste Heat Recovery Boilers - thyssenkrupp Industries India

Waste Heat Recovery Boilers System Description. TKIL Industries perfectly understands the pulse of your Cement plant and stands committed to deliver efficient power solutions to empower cement business of our customer’s cement business.

Sustainable transition towards biomass-based cement industry: A

2022年7月1日 To compensate and provide a solution for the complexities involved, it is inevitable to deploy policies that aid cement industries towards a sustainable circular bioeconomy. Transition studies focusing on biomass

Alternative Fuels Substitution in Cement Industries for Improved

2023年4月19日 The conventional energy source in cement industries is fossil fuels, mainly coal, which has a high environmental footprint. On average, energy expenditures account for 40% of the overall production costs per ton of cement. Reducing both the environmental impact and economic expenditure involves incorporating alternative

Cement kiln - Wikipedia

Portland cement clinker was first made (in 1825) in a modified form of the traditional static lime kiln. [2] [3] [4] The basic, egg-cup shaped lime kiln was provided with a conical or beehive shaped extension to increase draught

Investigation of Waste Heat Recovery in Cement Industry:

Index Terms—Energy saving, cost saving, pre-heater, cement industry. I. I. NTRODUCTION. The cement sector is one of the most energy intensive industries. The clinker calcination process is the most energy exhaustive in cement production, because of the exit gases from the clinker cooler and pre-heater at the head and tail of a

Alternative Fuels Substitution in Cement Industries for

2023年4月19日 The conventional energy source in cement industries is fossil fuels, mainly coal, which has a high environmental footprint. On average, energy expenditures account for 40% of the overall production

Preheater, kiln, and cooler flow sheets in Aspen Plus

Download scientific diagram Preheater, kiln, and cooler flow sheets in Aspen Plus from publication: AspenPlus based simulation for waste heat recovery in cement industries Cement manufacturing ...

Energetic and exergetic analysis of waste heat recovery systems

2013年9月1日 Waste heat recovery is feasible for a cement industry and it can offer about 6 MW of electric power for a typical cement plant. The preheater and clinker cooler exhaust gases are the heat sources for the heat recovery systems. Two different cycles were investigated; a water-steam cycle and an ORC with isopentane as working fluid.

Optimization of the Preheater Cyclone Separators Used in the Cement

2012年1月1日 of preheater cyclone separators used in the cement industry. The process parameters have been analyzed under varying vortex finder diameters (80, 120, and 160 mm), lengths of vor-

Investigating energy saving and climate mitigation potentials in cement ...

2023年7月1日 It is estimated that the cement industry consumes about 7% of the world’s industrial energy consumption, indicating that the sector is highly energy-intensive [4].In the cement-making process, different sources of energy have been utilized, either in the form of electrical energy or thermal energy [8].To produce a tonne of cement in a dry process

In-Line Calciner Preheater System - FLSmidth

Getting the right preheater calciner system will have a big impact on your cement plant’s operational efficiency, emissions, and ability to burn alternate fuels. Our In-Line Calciner Preheater System, first introduced in 1976 and continually updated and improved, will help you meet emissions requirements and optimize fuel and power consumption.

Pyroprocessing and Kiln Operation - Indian Cement Review

2023年1月16日 Pyro-processing in a cement plant comprises a preheater, rotary kiln and clinker cooler. ... The capacity utilisation of cement industries decreased from 66.2 per cent in 2018-19 to 60.3 per cent in 2021-22. There was contraction in demand and production during the pandemic.

Heat Integration in a Cement Production IntechOpen

2017年10月20日 1. Introduction. Nowadays, cement manufacturing is an energy-intensive industry. The energy costs of cement industry are about 40% of the product cost that indicates that this sector is one of the biggest CO 2 emitter. The global anthropogenic CO 2 emission of cement industry is approximately 5% [].The International Energy Agency

2-12-24SERVICE MECHANISM

Common choice of more than 170 countries

Email:[email protected]

المحادثة على الإنترنت

المحادثة على الإنترنت